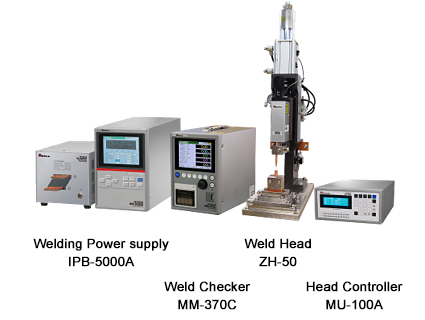

HEAD CONTROLLER MU-100A

Liên hệ để biết giá

Features

- ■ Weld head control and force and displacement measument.

- Head Control and sequence function not provided by MM-Series weld checker are available.

Nine types of measurement modes with a variety of functions including monitoring displacement before welding and setting internal zero reset. - ■ Corresponding displacement sensors and load cells are newly added.

- The displacement sensor is available from 0 to 25mm, and the load cell is from 0 to 10kN.

Contact AMADA WELD TECH for more information. - ■ Up to four channels to monitor simultaneously: Two force sensors and two displacement sensors.

- Available even when series welding, parallel gap welding, and indirect welding.

- ■ Up to 127 schedules can be saved.

- ■ Offset adjustment of controller for each sensor

- * For calibration, please send us your displacement sensor and force sensor together with the MU-100A. We conduct calibration at our site and issue calibration certificate with charge.

* The calibration is conducted for only the sensor purchased from AMADA WELD TECH.

* For the load cell with 10kN or over, contact AMADA WELD TECH.

Specifications

| Model | MU-100A-00-00 (1-axis type: Force 1 and Displacement 1) |

|

| MU-100A-00-01 (2-axis type: Force 2 and Displacement 2) |

||

| Power supply | Single-phase, 100 to 240 VAC±10% (50/60Hz), 0.5 A | |

| Operating environment | Temperature 5 to 40℃, Humidity 90% or less | |

| Storage environment | 0 to 55℃ | |

| Number of schedules | 127 | |

| Communication | Ethernet, RS-232C, RS-485 | |

| Displacement sensor (Options) |

Measurement range | 0 to ±50.000 mm *1 30-mm displacement sensor or shorter:±0.015 mm *1 50-mm displacement sensor: ±0.025 mm *1 |

| Load cell (Options) |

Measurement range | 0 to 10kN *2 (Accuracy: ±3% of full scale) |

| Mass | 3.3kg | |

*1*2 In case of using the sensor purchased from AMADA WELD TECH.

*2 For the load cell with 10kN or over, contact AMADA WELD TECH.

Connection with peripheral devices

- Futher welding quality control can be realized using with our weld checkers.

Measurement Mode

You can choose from nine measurement modes in accordance with your requirement.

| Sequence Mode |

|---|

| Measures the thickness of a workpiece before welding and measures its displacement value after welding. |

|

| Sample Hold 1 Mode |

|---|

| Measures the thickness of a workpiece at your designated point. |

|

| Sample Hold 2 Mode |

|---|

| Measures displacement after zero-resetting prior to welding. It stops welding when the displacement value reaches the set value. |

|

| Sample Hold 3 Mode |

|---|

| Measures the thickness of a workpiece and its displacement at a given point in time. When to start and end measuring can be set. |

|

| Synchro Mode |

|---|

| Measures force, the thickness of a workpiece, and displacement both before and after weling. |

|

| (Force) Sequence Mode |

|---|

| Measures force prior to welding and starts welding when the force is judged to be appropriate. |

|

| (Force) Sample Hold 1 Mode |

|---|

| Measures force at a given point in time. |

|

| (Force) Sample Hold 2 Mode |

|---|

| Starts welding when the force reaches the set value and measures the maximum force during welding. |

|

| Tangential Mode |

|---|

| Starts welding when the force reaches the set value and measures force after welding. |

|

English

English